Previous Page --

INDEX --

Next Page

EZ Tunnel Race Boat Plans

Page Nine

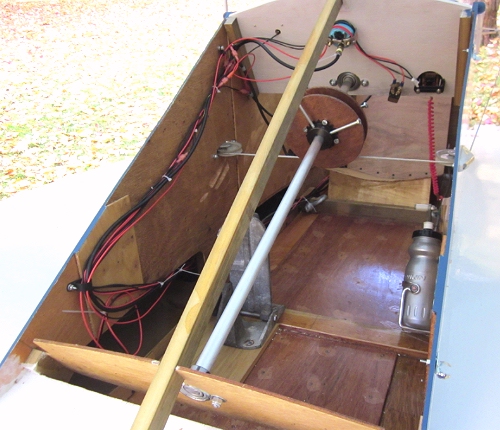

Steering System

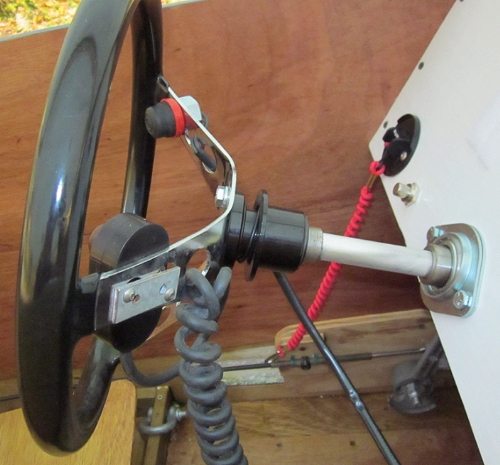

The steering system starts with a 3/4-inch diameter metal steering shaft mounted on bearings bolted to the dashboard and cowling bulkhead. Install the dashboard bearing as close to bottom edge of the dashboard as is practical. The other bearing should be installed as close to the top edge of the cowling bulkhead as is practical.

The steering drum, mounted on the shaft, spools the 1/8-inch cable which runs through coaming pulleys and then aft to the steering arms on the motor.

I have found that 3/4-inch steel rod, of the sort you can typically get at hardware stores, fits 3/4-inch bearings and other components quite accurately. Aluminim rod, on the other hand, tends to be over-sized and has to be laboriously sanded down to make it fit. The aluminum rod is about 3 lbs. lighter than the steel. If the weight savings is important to you, then go with the aluminum and do the work.

I purchased my steering bearings at Surplus Center in Lincoln, NE. (I will mention other components available at Surplus Center later in these notes.)

Steering drums can be purchased at places like Brown Tool & Machine and Sorenson Woodcraft.

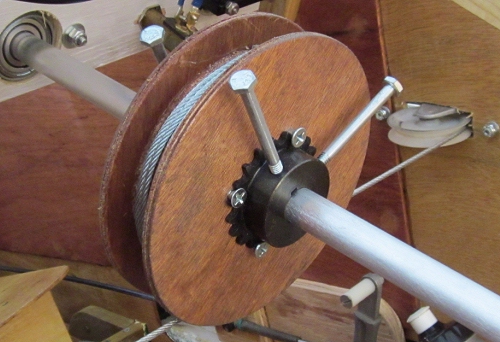

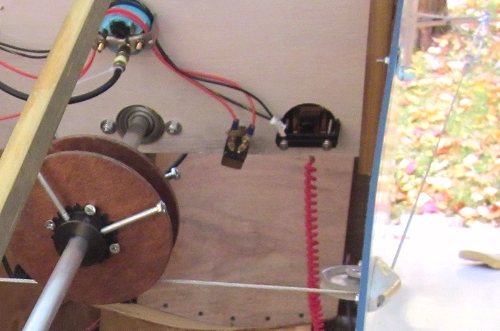

I've gotten into the habit of making my own from plywood discs. Four or five 5-inch discs are sandwiched between two 6-inch discs. A 3/4" hole is drilled through. A sprocket (or a pulley wheel) is screwed to each face. I like to replace the set screws in the sprockets with bolts for easier access.

These sprockets, from Surplus Center, are not described by their diameter, but by number of teeth and pitch. My drum has 20-Tooth, 35-Pitch sprockets.

Coaming pulleys are also available at Brown Tool & Machine and Sorenson Woodcraft.

Note that the cable emerges from the bottom of the steering drum and intersects the coaming at a 90-degree angle. Thus, you will want to purchase coaming pulleys with a 90-degree base.

The cable emerges from the coaming, through the coaming pulleys, and then rises toward the steering arms on the motor. You will need to know, at least generally, the height of your steering arm ends before mounting the coaming pulleys.

The steering cables are bent around thimbles and clamped with two cable clamps each side. The thimbles are attached to the steering arms with shackles.

The steering arms are made from 1/4" X 2" aluminum bar. The braces are made from 1/4" X 1" aluminum.

On the Johnson/Evinrude motors we use for GT Pro racing, there are already holes located in the back of the pan, though they will need to be drilled through. I can't speak for other motors.

The braces are attached about six inches from the cable shackles, and to the steering bracket on the motor. The motor's bracket already has 5/16" threaded holed which you can use.

The arms are approximately 24 inches long; the distance between shackles is approximately 36 inches. Set up the arms so that the shackles are directly opposite the tilt tube on the motor. That way, cable tension will not change as the motor is trimmed up or down.

I like a steering wheel in the 11-inch to 12-inch diameter range. A good example is the Grant 334 which is available on Ebay through such sellers as Jegs and Summit. May also be available on Amazon.

The steering wheel is mounted on the steering shaft using a quick-release hub. These are also available on Ebay, and through dealers of racing equipment.

The fixed part of the quick-release hub is attached to the steering shaft by drilling a 1/4-inch hole through the part and the shaft and tapping in a 1-inch long roll pin.

Previous Page --

INDEX --

Next Page